Inventory management is one of the most critical functions for a company because its turnover is what creates revenue for the company. Inventory involves receipt of materials, parts, or manufacturing of finished goods.

The main functions of inventory involve meeting anticipated demand for the products, safeguard against stock-outs and facilitate production requirements. Let’s briefly understand about the three types of Inventory.

Raw Materials: They are the raw products that are used in making the finished products through a manufacturing process. It is important to arrive at the Economic order requirements for raw materials based on the manufacturing plan. Note that this changes between companies & industries.

A company that has standard production schedule which is derived from the sales plan will always have the raw materials defined, however if you look at the made to order industry the requirement will vary basis multiple factors i.e quantity, availability, shipping time, order cost etc.

WIP: Goods that are partially completed and are in the process of becoming finished goods.

Finished Goods:

Wikipedia defines Finished Goods as below:

When the good is completed as to manufacturing but not yet sold or distributed to the end-user, it is called a “finished good”.

This is the last stage for the processing of goods. The goods are ready to be consumed or distributed. There is no processing required in terms of the goods after this stage by the seller.

However, in the supply chain management flow the finished goods of one supplier can be a raw material for another manufacturer and hence, finished goods is a relative term.

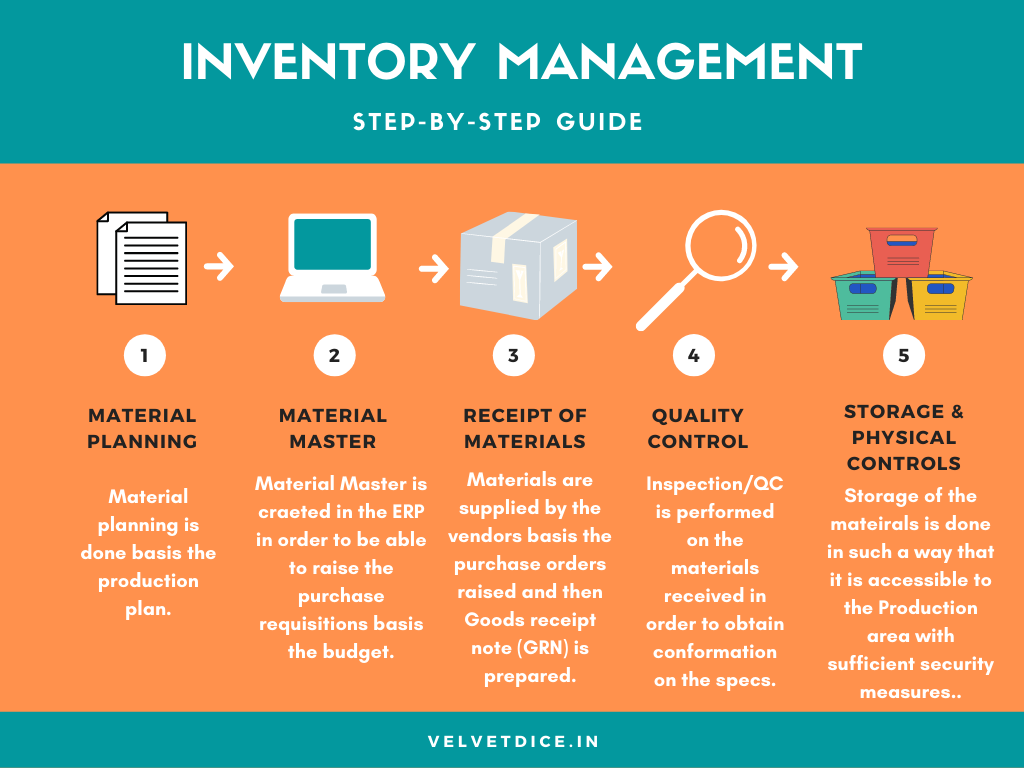

Now let’s dive into the Inventory process and the analytics that can be done as part of Internal Audit:

We will be discussing in detail about Internal Audit in the following articles, but here are some key Internal Audit analytics indicators that can be helpful to start an audit with:

Companies have to leverage technology to ensure that the controls that are put in place are in deed functioning as they are expected to be. The future is dependent on much more robust systems that can reduce the work load of man power in the mundane inventory management activities. Companies have to ensure that they place strong access controls, segregate the duties, have strong controls supported by able technology and have audit trail for all the movements of the Inventory.

Concluding the article with this. We will look into much more detailed Internal audit techniques for Inventory Management. Until next time !

Leave a Reply